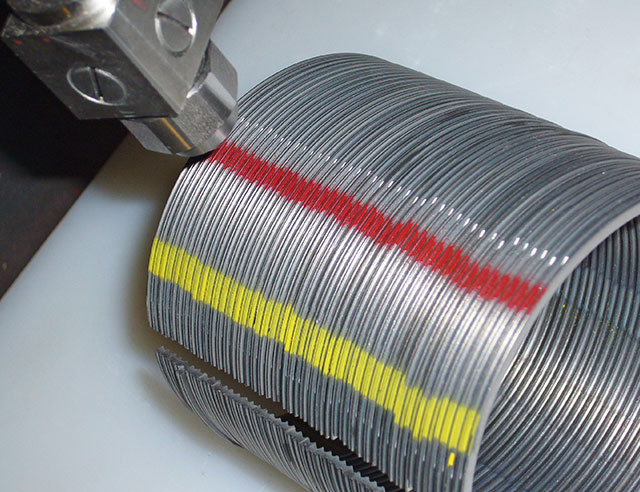

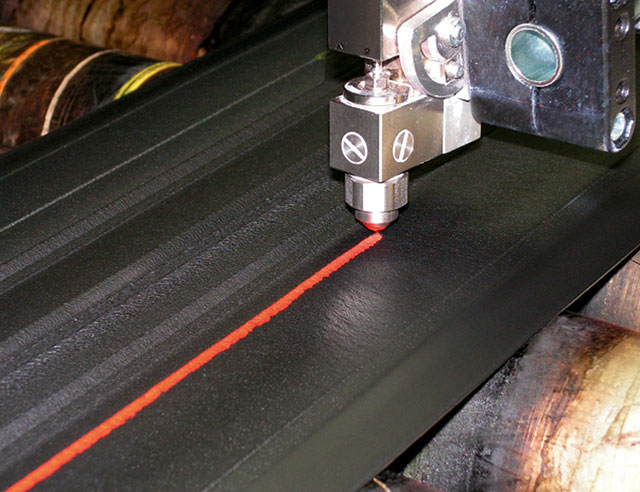

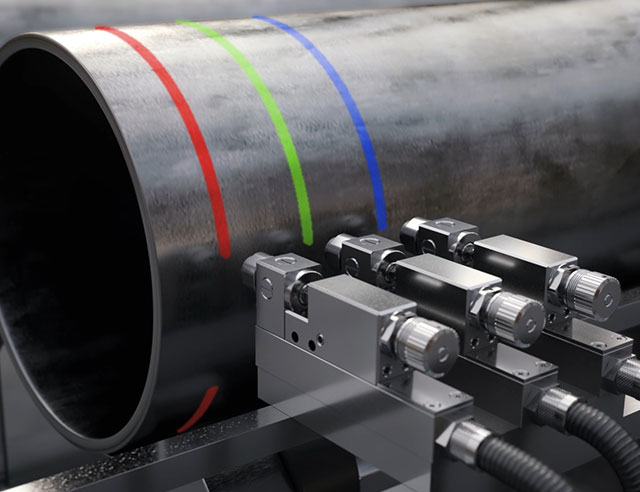

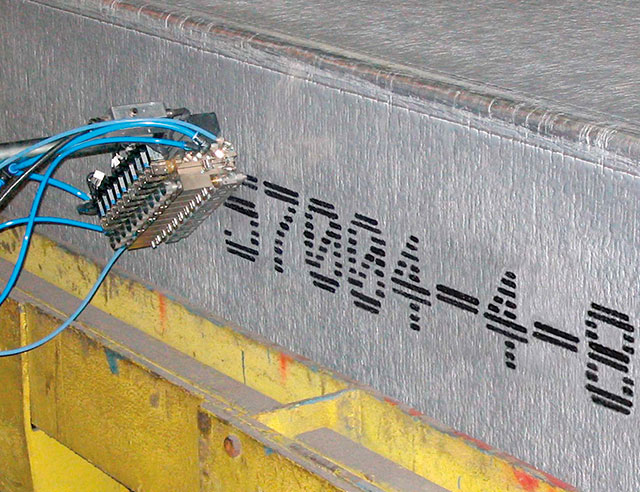

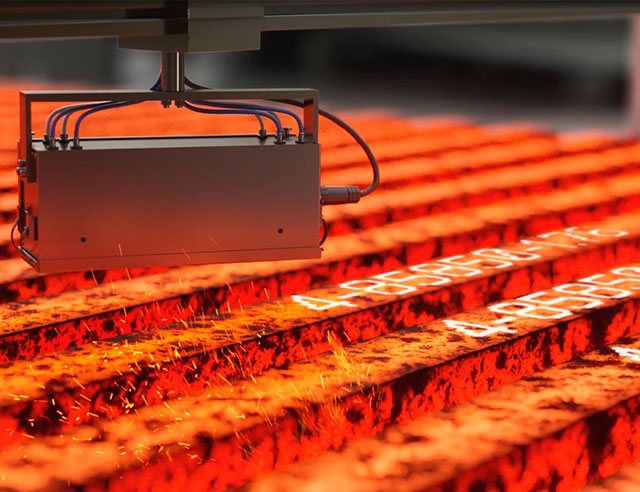

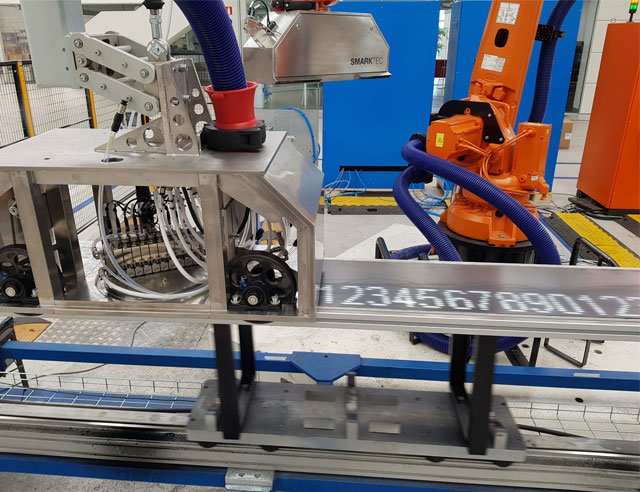

High quality marking and precision line tracing

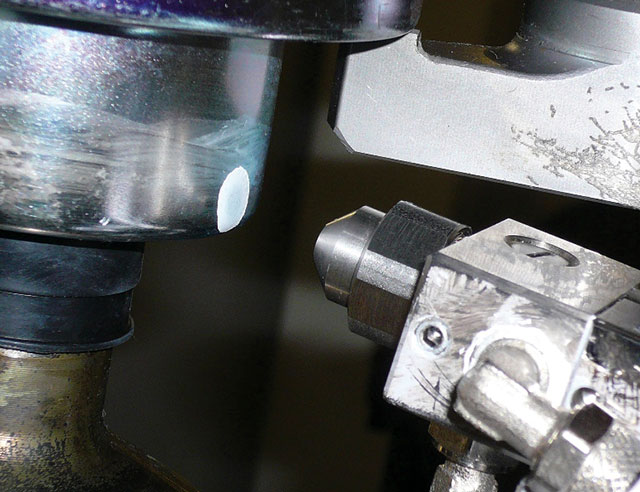

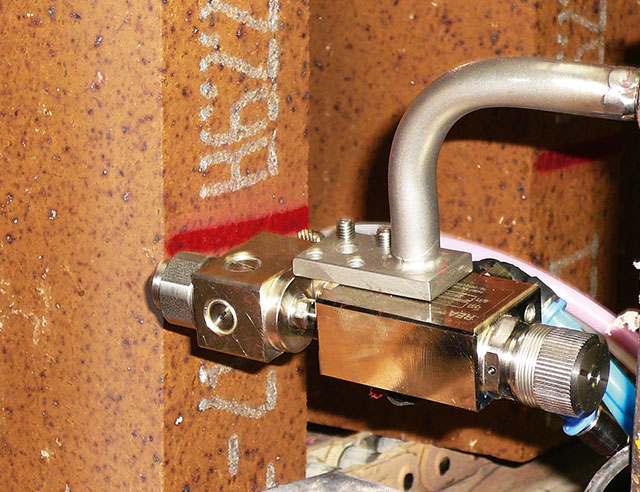

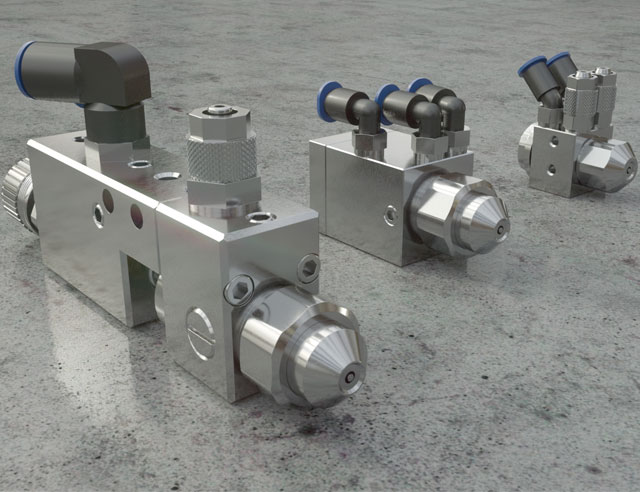

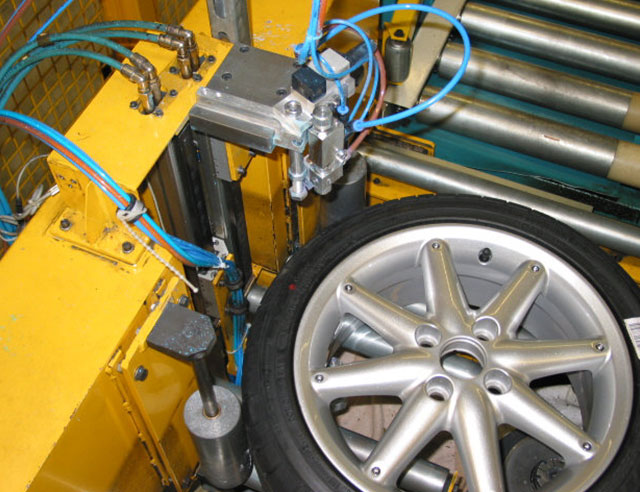

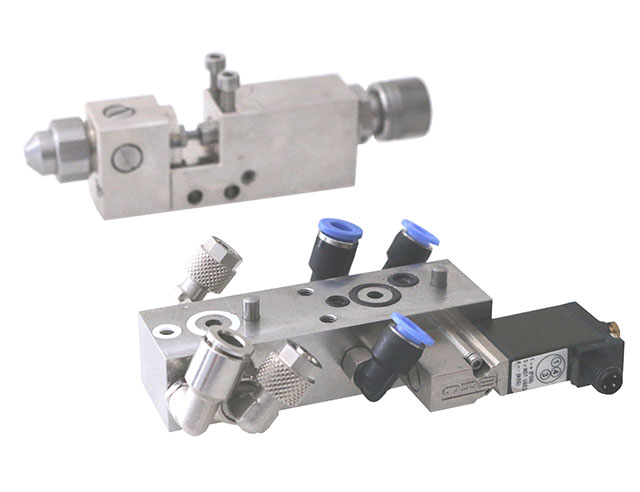

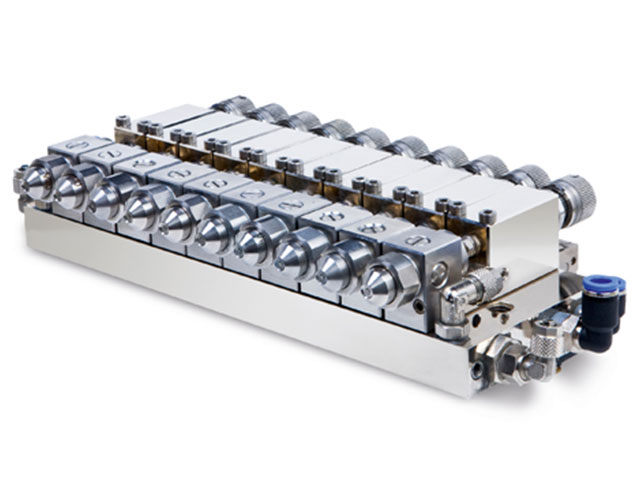

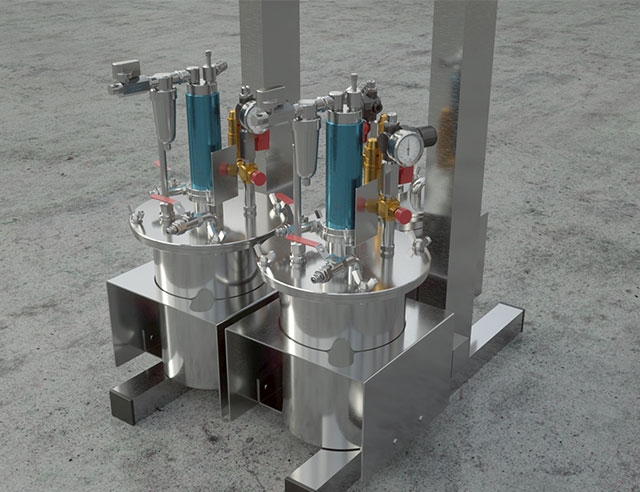

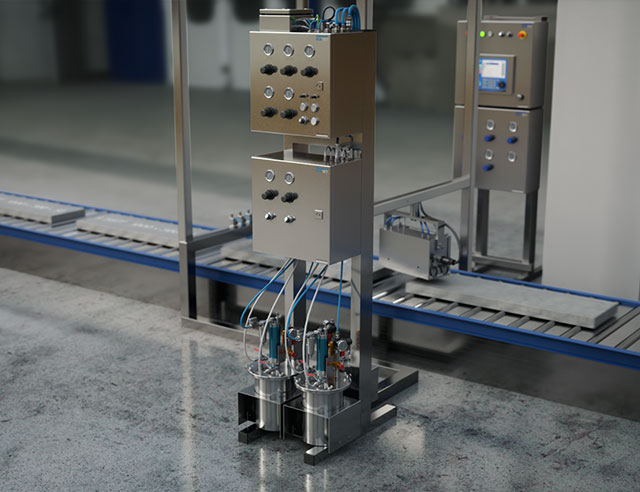

Color-coded markings are crucially important to many technical areas. In industrial applications, color-coded markings provide information about product quality and condition, regulate processes and determine procedures. Whether dot marking in red, indicating inspected quality in green or colored line marking for pipes, profiles or continuous products – REA Spray Marking Technology has even more to offer: Using spray mark heads as a spray mark block, one can write large texts, up to 700 mm in height. Dot by dot!