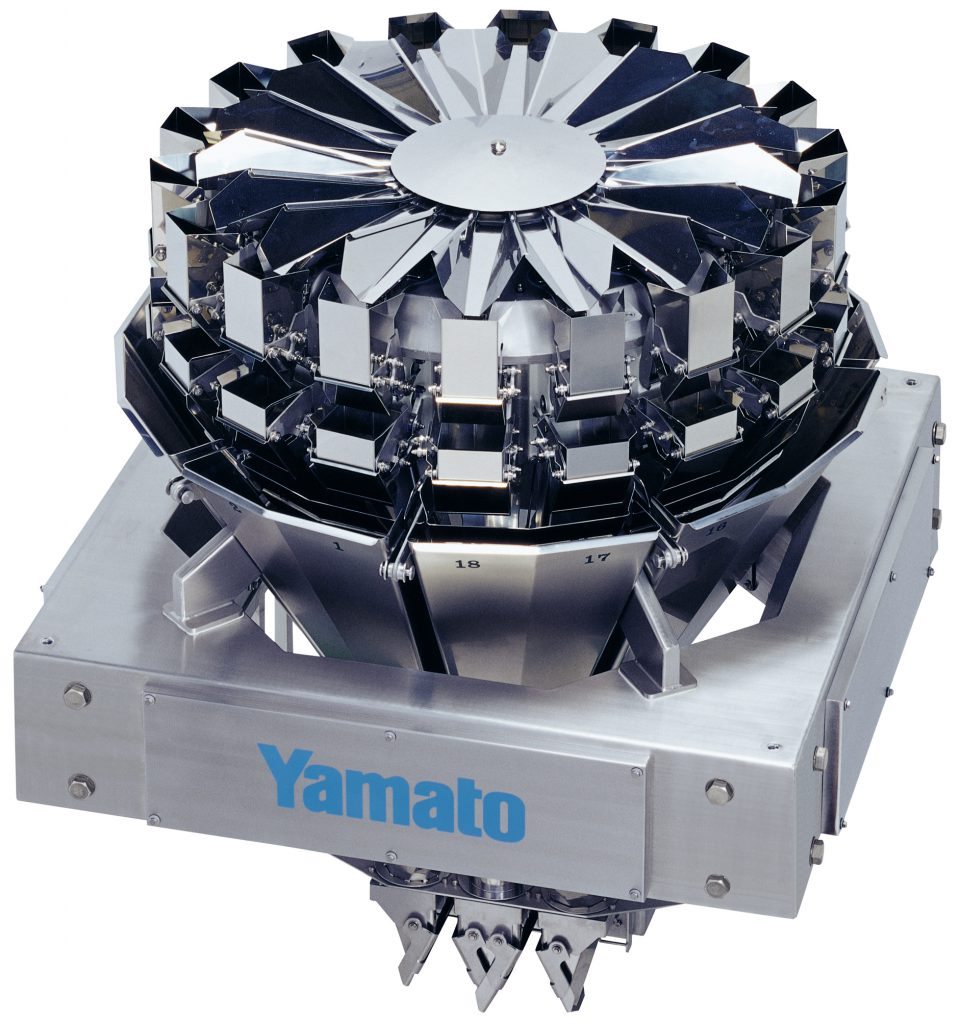

The benefits of the Yamato SIGMA F1-Frontier-Series:

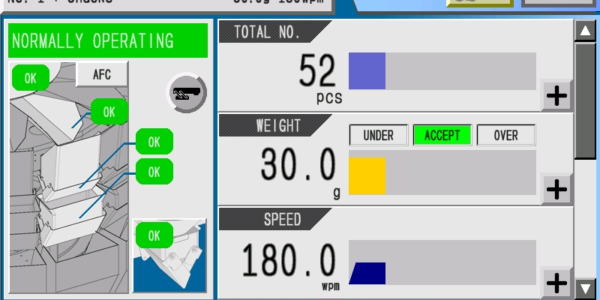

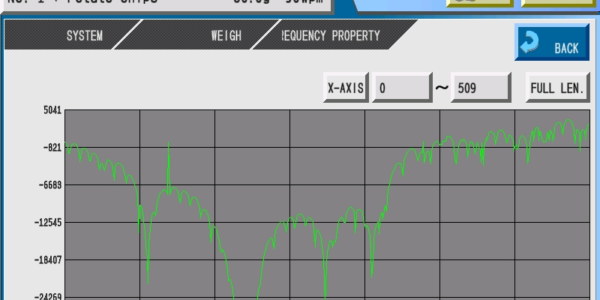

Technology

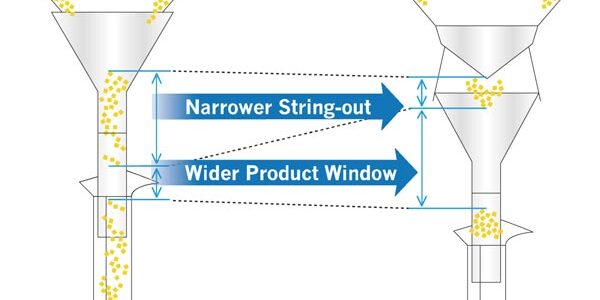

Simplicity of design and structure offers:

- Improved combination accuracy and speed with the minimum number of buckets

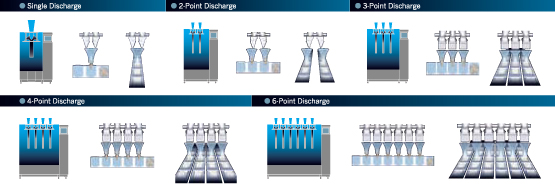

- Simultaneous combination capability offers cost effective application interface