Warning: Array to string conversion in /home1/safeautomations/public_html/wp-content/plugins/iks-menu-pro/includes/core/utils/RenderUtils.php on line 72

Conveyors

Conveyors

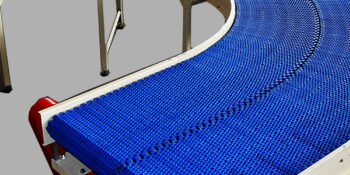

Modular Belt Conveyor

Modular belt conveyors are extremely robust and can be used in a multitude of ways for almost every transport application. The belts are wear resistant and can even be used to transport product with sharp edges. It suitable for food, suitable for high temperatures or resistant to chemicals.

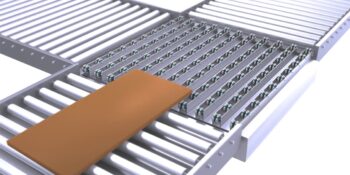

Roller Conveyor

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

PU Belt Conveyor

In nearly all industrial applications, belt conveyors handle the majority of material transport tasks. They are suitable for transporting both packaged and unpackaged piece goods with a wide range of shapes and dimensions.

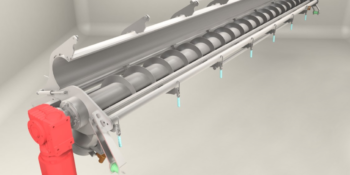

Screw Conveyor

Screw conveyor is a kind of conveying machine that uses motor to drive spiral rotation to move materials to realize transportation. It is suitable for horizontal & vertical conveying of particles or powdered materials. It is a widely used in mineral, feed, grain and oil, construction industry.

Food Grade Conveyor

Food conveyors move foods and other organic materials through their processes safely and quickly. All at a fraction of the cost of manual labor the same task. The term “food conveyor” covers a wide variety of systems ranging from roller, belts and dumpers.

Wedge Conveyor

A wedge conveyor has two conveyors arranged in parallel to each other which can be quickly set at variable widths by means of the adjustment unit (AL).

Side Grip Conveyor

Side grip conveyors, also referred to as side belt conveyors, utilize parallel belts that grip product securely by the sides, enabling product to be conveyed while providing access to tops and bottoms. Product is held firmly in place during transfer across steep inclines. Industries such as the packaged-food and pharmaceutical industries, among many others, have benefited from these solutions.

Retracting Conveyor

A retractable conveyors are prized for their remarkable ability to enhance system flexibility. Retractable conveyors, also known as retracting conveyors and retractable tails, are conveyor frames that can retract, or extend, manually or pneumatically and typically on slides or rails. This function can happen infrequently with low accuracy or reoccur every few seconds with precision.

Loading / Unloading Conveyor

Loader-Unloader Conveyor unit for all application like for boxes, cartons, bags, etc. in warehouse, bottling plants, distilleries etc. and any places where material needs to be moved rapidly & efficiently. This conveyor is mostly reduce maximum labour & save time. These conveyor features are easy movability, slider bed design, zero maintenance.

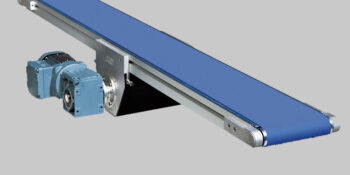

Flat Belt Conveyor

Flat Belt Conveyors are Belt Conveyors in which the carrying run is supported by flat-belt idlers or pulleys. To align a flat belt conveyor simply adjust the tail end pulley or the idler pulley, it is provided with adjuster bolt to adjust it in order to align the conveyor.

Bulk Material Conveyor

A bulk material conveyor is a machine or device designed to transport large quantities of loose materials. These types of conveyors can be found in factories, warehouses, and agricultural settings, where they are used to move items ranging from powdered chemicals to grains.

Spiral Conveyor

The Spiral conveyor is a compact and versatile elevating solution. Spiral can be designed to carry product between floors and machines or over aisles. Designed with a uniform slope, the Spiral conveyor ensures smooth operation without disturbing the product.

Cleated Belt Conveyor

Cleated belt conveyors provide many purposes in today’s manufacturing environment. They are used to help move product up inclines, as well as stage product to operators or to provide predictable spacing on a line. With five standard conveyors that can have cleats attached to them, Safe Arabia is sure to have the right conveyor for your application.

Pallet Conveyor

Pallet conveyors transfer discrete products on carriers referred to as pallets typically transported by belt, roller chain, flat-top chain, or for extremely high loads, powered rollers

Bucket Elevator

In simple terms, bucket elevators vertically convey bulk materials. They are considered similar to conveyor belts, with the greatest difference being that bucket elevators move material using buckets attached to a rotating belt or chain. The buckets work to pick up material, move it to endpoint, discharge return to pick up a new load.

Trough Conveyor

Trough Conveyors are designed to help keep loose or bulk materials in the center of the conveyor. The belt is troughed with rollers, rails, or with a slider bed that the belt conforms to. Trough belts are great for conveying loose or bulk materials, especially if the material is abrasive.

Slat Chain Conveyor

Slat conveyors are a type of conveying technology that utilizes a chain-driven loop of slats to move product from one of its ends to another. The chain is driven by a motor, which causes it to cycle just as belt conveyors do.

Flexible Conveyor

Flexible conveyors let you change discharge points by rolling and curving conveyor sections to fit your needs. They’re commonly used at shipping docks or the discharge end of a conveyor system to connect to truck trailers. A single conveyor can serve multiple dock doors.

Vibrating Conveyor

Vibrating conveyors consist of troughs or tubes flexibly supported and vibrated by mechanical or electrical means to convey objects or bulk materials; vibration takes place in an inclined, elliptical pattern to cause directional as well as upward movement of the material.

Chute Conveyor

Chute Conveyor is one of the least expensive methods of conveying material. It is the simplest example of gravity-operated conveyor. Chute conveyor is used to provide accumulation in shipping areas; a spiral chute can be used to convey items between floors with minimum amount of space required

Accumulation Conveyor

Accumulation conveyors are designed to hold or stop items on a conveyor; or to put it simply, they accumulate product. Most commonly used to support picking and packing applications, accumulation conveyors create a temporary buffer zone between products moving up or downstream

Crate Conveyor

Cart Conveyor is easy to use and can run parallel with a passenger escalator or as a stand-alone unit. Referred to as trolley conveyors or buggy conveyors in different countries, these shopping cart conveyors are extremely advantageous in multi-level retail stores.

Trolley Conveyor

Trolley Conveyor is a series of trolleys with loads suspended from them, supported by an overhead track and connected by an endless propelling medium such as chain or cable. Trolley conveyor chain is used to carry goods hung under ceiling.

Gravity Roller Conveyer

A gravity roller conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and affordable types of material handling systems. They work by allowing the product to roll along the upper surface.

Omni Directional Conveyor

Omnidirectional conveyor belt that can move objects freely in any direction. Following is a transcript of the video. This conveyor belt can move in any direction. It consists of several small hexagonal cells driven by omnidirectional

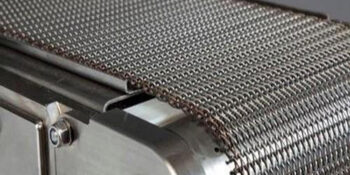

Trolley Conveyor

The Wire Conveyor Belt can be used in any kind of production line for transporting. The wire conveyor belt is from one place to another in production lines, transportation lines, oven lines, cooling and freezing lines, and is formed by weaving metal wires in various shapes.