EASY IDENTIFICATION – SAFE DISTRIBUTION

The XPU pallet labeler offers high levels of reliability, efficiency and user-friendliness, including demanding 24/7 applications, and delivers outstanding print results even in the rough conditions of a logistics environment.

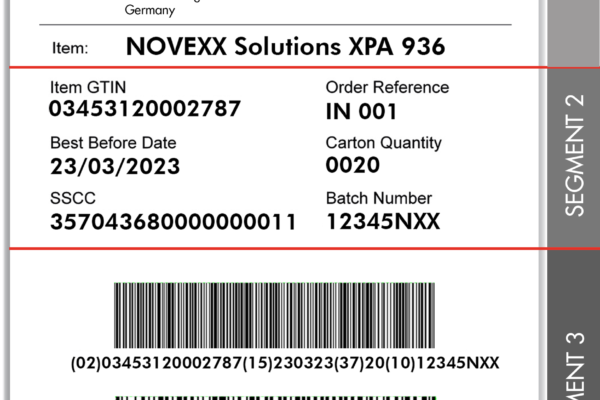

- Applies GS1 compliant DIN A5 labels

- Best print quality thanks to the integrated

XPA PRINT & APPLY SYSTEM - Labeling optionally 2 sides with just one pallet stop

- Labels up to 200 pallets per hour (with 2 labels)

- Scanner for barcode validation

- Options: 3 side labeling, 4” panel pc for machine status information and more

- Trace-it Pallet Labeling Software (server based or on panel PC) for label-, data- and process management